| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : LIJIANG GLASS

Model Number : LJBZ2025

Certification : CE

Place of Origin : JINAN CHINA

MOQ : 1 set

Price : USD 45000 - 60000 per set

Payment Terms : L/C, T/T

Supply Ability : 100 sets per month

Delivery Time : 40 days

Packaging Details : 2 * 40 HQ containers

Machine name : Insulating glass processing line

Max glass size : 2000 mm*2500 mm

Glass thickness : 3 - 15 mm

IG thickness : 50 or 60 mm

Color : Write / green / red and so on

Washing machine material : Stainless steel

Machine length : 16.7 m or 19.5 m

Optional function : Triple glass / step glass

Warranty : 1 year

Contacts : Hermione : +86 18353163989

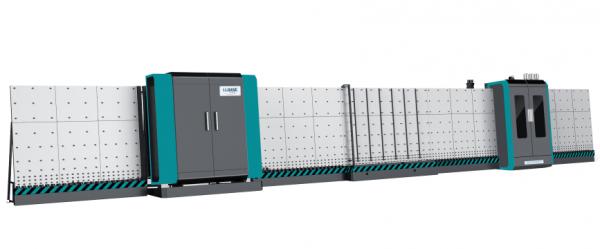

Automatic Insulating Glass Processing Line With Glass Washing Pressing Machine

LIJIANG's products mainly include:

IG line series;

Sealing robot series;

Low-e film edge deletion machine;

Spacer bending machine series;

Butyl extruder machine series;

Desiccant filling machine;

Auxiliary insulating glass machines.

About 20 products are widely used in customized insulating glass industry, windows and doors, industrial aluminum alloy, building curtain wall, high-speed rail, elevator and advertising industry.

Company profile of LIJIANG GLASS :

Jinan Lijiang Automation Equipment Co., Ltd (LIJIANG GLASS) specializes in the R & D and manufacturing of automatic insulating glass machinery since 2007. Domestic friendly partners include nearly one thousand customers, such as North glass, Xinfuxing, Yaohua, etc.

The products have been exported to Europe, the United States, the Middle East, Southeast Asia, South America,Romania, Bulgaria, Span and other countries (about 30 countries) of the world. At the same time, we have set up branches in New Delhi, India.

IG line series :

Sizes :

2000*2500

2500* 3500

3000* 4000

3300*7000

Special technology :

Shaped glazing glass

Filling argon gas online

Low-e film glazing glass

Making two pieces of IG units in once time

Air floating insulating glass line

Functions :

double glazing glass

triple glazing glass

four sides step glazing glass

Automatic Vertical Insulating Glass Production Line - 2000*2500

Main Features of Insulating Glass Production Line:

• IG line has 7 sections:

01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.

Washing machine:

Main feature:

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• Pre-washing (Optional)

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

• pressing and filling section

Pressing machine :

Main feature:

• Ultra-long (2500mm*3500mm) insulating glass can be compressed twice

• Adopts conveyor belt to transfer glass, uses servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

Technical data of insulated glass production line:

| Max. glass size | 2000mm*2500mm |

| Total length | 19.5 meters |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 50mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ |

| Warranty | 1 year |

| Weight | 6500kg |

Other products of LIJIANG GLASS

Automatic Insulating Glass Aluminum Spacer Bar Butyl Glue Coating Machine

Automatic butyl extruder machine is the necessary equipment for manufacturing aluminum-frame type insulated glass, even it is necessary for Vertical insulating glass processing line.The butyl that be glued on the both side of aluminum frame automatically, the glue is the first coating sealant for insulating glass. So the quality of the butyl directly decides the quality of insulating glass and using life. The butyl extruder machine have many types in the market, including manual and automatic butyl coating machines.

The Details Of Butyl Extruder Machine LJTB 01

Main feature :

• PLC control system, KINCO touch screen interface

• Hydraulic system using German brands

• Alarm system, reminding adding butyl glue

• The sensor can automatically measure the width of frame, the distance of nozzle can be adjustable

• Exhaust function

• Short preheating time, improve work efficiency

• Coating shape frames, the roller device can be selected at will

• Fast coating speed, can up to 47m/min

• Stable pressure and even coating

• Saving glue. The amount of glue on both sides can reach 4g / m

• Big glue barrel, 200L. (Optional)

Technical data :

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 6A - 27A |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Electrical parameters

| Name | Original | Brand |

| PLC | China | KINCO |

| Valve | German | HAWE |

| Low voltage electrical apparatus | German | SIEMENS |

| Hydraulic and pneumatic supercharging system | German | MAXIMATOR |

| Frequency converter | China | KINCO |

| Pneumatic components | Taiwan | ARTAC |

| Quick exhaust valve/Vacuum generator | Japan SMC | SMC |

| Travel light | Japan | OMRON |

| Optical fiber | Japan | OMRON |

Function description

This machine has kinds of functions, please see the below instructions:

(8)Automatic measure the width of aluminum spacers----device of thickness measurement it can automatic adjust the distance of back and front needles by width of aluminum spacers;

(9)Frequency control motor Transfer motor is frequency control motor and max speed can up to 47m/min.

(10) This machine is easy to operate, it’s stable and reliable, the effect of gluing is good, speed is quick and the product is efficient.

|

|

Automatic Insulating Glass Processing Line With Glass Washing Pressing Machine Images |