| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : LIJIANG GLASS

Model Number : 2230

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Supply Ability : 40 Set per year

Delivery Time : 60 days

Packaging Details : container

Product Name : Vertica insulating air-floating glass processing line

Voltage : 380V 50Hz 3P

washing speed : 2-10m/min

Maximum working speed : 45m/min

Flat glass thickness : 3-15mm

washing brushes : 6pieces

Double Glazing Insulating Glass Production Line Jumbo size 3300*7000mm For Insulating glass processing

Main feature of Double Glazing Insulating glass Processing Line

●Germany Siemens PLC control system,touch screen interface

●Automatic identification of coated and Low-E glass

●3pair soft brushes can wash online and offline Low-E glass

●The washing machine adopts SS material and waterproof device

●Adjustable pressing board to keep the plate pressing surface straight

● Connection mode of aviation plug

●Water tank with automatic temperature control and water washing system

● Air heating system

●Air Fan automatic start and stop setting

●Noise reduction system

●Applicable to produce triple IG and shaped IG

●Online display of washing speed

●Intelligent intermittent work, saving energy

Options of Automatic Jumbo size double gas filling insulating glass line

1.Pre-washing

2.Automatically accurate positioning for 3 or 4 side step IG

3.Automatic gas filling can set gas value and display the processing of filling online with high gas concentration

1. What is the IG line ?

The types of the IG line are without filling argon and with filling argon gas. There are also two special IG lines, air floating IG line and super fast IG line (washing and pressing two IG units together).

The IG line is calles insulating glass processing line, it includes glass washing machine, spacer frame installation and glass pressing machine. We normally have 2000*2500, 2500*3500, 2500*4000 ,2500*4500 and 3300*7000 IG line.

2. What does our company do ?

LIJIANG GLASS is the manufacturer in Jinan city, China since 2012 year. We make the IG line, Insulating glass sealing robot, spacer bending machine, butyl extruder machine desiccant filling machine and so on, porviding machines for all over the world with after sale service.

3. How to provide after-sales service ?

For India and the market aroud India, we have two Indian loal engineers, they can provide service in time.

For South America market, we have one engineer there to provide service.

For other market, we have the engineer team with 10 - 20 years experience, they will go to foreign customers' factory to install machine, train workers and provide after sale service in time.

Since the virus of the whole world, Our engineers are restricted to many countries in the world. So we provice installation service and trainning work online by Wechat, Whatsapp and so on. Once the world has a better suitation, our engineer will go to check our machines again.

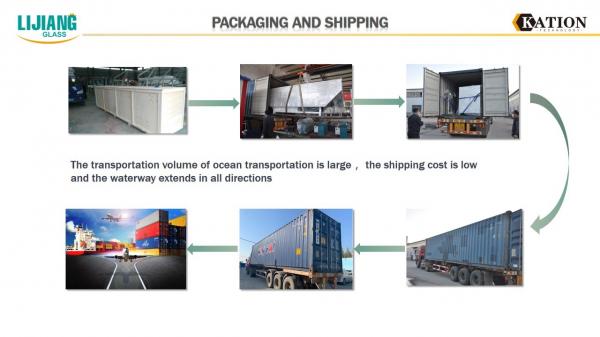

4. How to package production line ?

One set of IG line normally needs two containers when shipping to foreign country, 2 pieces of 40HQ containers.

Details of Automatic Insulating glass production line :

• Vertical Insulating glass production line has 7 sections:

01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.

• 01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

• 02 washing machine

Main feature:

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• European silencer system

• Stainless steel material

• 03 discharge section

• Storage glass

• 04 inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass.

• 05 transfer section

• Automatic measurement of glass thickness. It can be used according to actual needs when working.

• 06 pressing and filling section

Main feature:

• Ultra-long glass can be compressed by twice

• Adopts conveyor belt to transfer glass, use servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• 07 discharge section

• Storage glass

• Can be connected to sealing machine

Parameter of Vertical Automatic Insulating Glass Production Line

| Unit | LJBZ3370 | |

| Voltage | 380V50Hz3P | |

| Total power | KW | 54.5 |

| Washing speed | m/min | 2-10 |

| Maximum working speed | m/min | 45 |

| Minimum glass size | mm | 450*280 |

| Maxmum glass size | mm | 3300*7000 3000*3000 (Double press) |

| Flat glass thickness | mm | 3-30 |

| Washing brushes | Pieces | 6 |

| Maximum thickness of insulating glass | mm | 80 |

| Total gas consumption | L/min | 1500 |

| Conveyer roll height | mm | 520 |

| Dimension (L*W*H) | mm | 47200*3500*4500 |

Electrical parameters

| NAME | ORIGIN | BRAND |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Servo motor for step glass | Japan | FUJI |

| Photoelectric switch | Germany | SICK |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| Touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Brush motor | China | QINGHUA |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

Pictures of automatic insulating glass production line

Related Production of LIJIANG GLASS

Automatic Butyl Machine With CE Hot Melt Butyl Extruder Equipment for insulating processing

Aotomatic Bulyl Extruder Machine with high quolity

Application

PLC control system,touch screen interface

Automatically adjust the amount of glue according to different speeds

Automatically identify the width of aluminum bar,accordingly glue nuzzle can adjust automatically.

Hydraulic systerm uses German components to ensurethat the glue is even and full

Fast preheat,improve work efficiency

with preheating function

With exhaust and inflatable function,improve coating quality and asve time for feeding glue

Quickly coating speed,can up to 47m/min

Squeeze pressure:10-18MPa

Temperature:110-140℃

Aluminumspacerwidth:6A-27A

Speed:5-47m/min

Diameter of butyl cylinder:200mm

Air supply:0.4㎡/min

Air pressure:>0.6Mpa

Total power:380V,5.7KW,50HZ

Dimension:2800*700*900mm

Weight:650kg

Tech parameters of Automatic hot melt Extruder Machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 0-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 750kg |

Equipment details of Automatic Butyl Extruder Insulating Glass machine

Germany Siemens parts

Butyl extruder machine Adopt German brand Siemens PLC, stable performance.

KINCO Touch Screen

Use toubh screen operation ,simple trial,Clear interface, Simple operation, Smart touch screen,Updated programming.

Germany HAVE Valve

High speed butyl extruder machine Adopt Germany’s Harvey valve, more stable performance.

Alarm system

Adopt Automatically alarm system, reminding adding butyl.

Glue cylinder

The rubber cylinder adopt the pull-up structure, which is convenient for changing butyl.

Germany Maximator Cylinder

Super charging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

Adjust the glue putput automatically according to the speed change

The height adjustment of beam is convenient,effective to solve the provlem of white line

Other product of LIJIANG GLASS

Spacer Bending Machine With Aluminum Bars And Warm Bars

Application

The full automatic spacer bending machine is used for making frames ( or other materials) for insulating glass, which replaces the traditional fabrication technology. The Automatic Spacer Bending Machine With Aluminum Bars And Warm Bars can make a variety of convex polygonal aluminum frames by one aluminum strip in one time. The bending machine is available to bend aluminum bars, stainless steel bars, warm bars and thermex and so on. Also on the bending mahcine, also contains printing code , printing label , drilling holes and USB, machine hand for support big frame

Equipment details

Leading Technology

Technical data

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Electrical parameters

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | JAPAN FUJI | Solenoid valve | Taiwan AIRTAC |

| Servo driver | JAPAN FUJI | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

Vertical Auto Industry Flat Glass Washing and Cleaning Machine

1. Overview of Auto Vertical Glass Washing and drying Machine

Auto Industry Flat glass washing machine is used for glass washing for processing Double glazing glass.Auto vertical washing and cleaning machine can complete the following functions: pre-cleaning, cleaning and drying of flat glass and low-e glass.It is in the production of slot aluminum insulating glass. Glass washing machine has the advantages of small occupation area, high efficiency, reliable performance and convenient maintenance.

2.Advantage of glass washiing machine

•Using 3Pair of soft brushes with 0.1mm soft hair, can wash low-e glass

•Pre-washing (Optional)

•The air knife can automatically adjust the width of the air knife according to the thickness

•New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

•European silencer system

•The operation box with washing speed display, can accurately display washing speed (8-10m) •Water tank automatic temperature control, water replenishing system

•Stainless steel material

3.Main feature of vertical glass washing machine

4. Tech Parameters of Vertical Glass cleaning and Drying Machine

| Power supply | Voltage(V) | 380 |

| Frequency (Hz) | 50 | |

| Main power | kW | ≈35 |

| Washing speed | m/min | 1~7 |

| Max high speed | m/min | 10 |

| Min glass size | mm | 450×280 |

| Max glass size | mm | 2500×4000 |

| Glass thickness | mm | 3~15 |

| Roller height | mm | 500±20 |

| Total weight | kg | ≈3500 |

5. Detail of AutomaticGlass Washing Machine

Introduction of LIJIANG GLASS

APPLICATION

The double glazing glass processing line ( with gas filling) consists of four sections, transfer section, washing section, inspection section and pressing section (Totally 7 parts). It uses advanced technology to make high-quality and variety DGU automatically, such as double glass, triple glass, Low-e glass, shaped glass and stepped glass. Whats' more, a new IG line which can fill two pieces of double glass at the same time.

| Model | Min size | Max size | Low-e glass | Step glass | Triple glass | Filling gas (G) |

| LJBZ1825 | 300*500 | 1800*2500 | √ | √ | √ | √ |

| LJBZ2025 | 300*500 | 2000*2500 | √ | √ | √ | √ |

| LJBZ2230 | 300*500 | 2200*3000 | √ | √ | √ | √ |

| LJBZ2530 | 300*500 | 2500*3500 | √ | √ | √ | √ |

The low-e glass / Step glass / Triple glass / Shaped glass / Filling gas functions are optional. And The size of LJBZ2535G IG line with filling gas can fill gas into the max glass of 2500*3200mm, not 2500*3500mm.

Parameter Datas

1. Production name :Insulating glass processing line with press panel and filling gas

2. Model : LJBZ2535G

3. Origin place : JINAN , CHINA

4. Glass thickness : 3 - 15mm

5. Insulating glass thickness : 60mm

6. Glass washing speed : 2 - 10m/min

7. Glass conveyor speed : 48m/min

8. Washing brushes : 3 pairs of soft brushes

9. Materials of washing machine : Stainless steel

10. Function : Making DGU/Step glass/ Shape glass/ Triple glass/ Filling argon gas

11. Max glass size : 2500*3500mm

12. Max glass size for filling gas : 2500*3200mm

13. Warranty : 12 months

14. Color : Blue ( Bright white), many colors can be customerized

15. Length : 23.5m

16. Direction: Right to left

17. Shaped glass: One side must be straight

18. Min glass size: 450*280mm

19. Height (Rollers to ground): 520mm

20. Step glass : Small glass is inside or outside

MAIN FEATURES

|

|

Double Glazed Insulating Glass Production Line Jumbo Size 3300*7000mm Images |