| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : LIJIANG GLASS

Model Number : LJGZ2535G

Certification : CE

Place of Origin : JINAN CHINA

MOQ : 1 set

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 50 sets per year

Delivery Time : 2 months

Packaging Details : Containers

Product Name : Insulating glass processing machine

Voltage : 380V 50Hz 3P

Min. glass size : 280*400

IG thickness : 60mm

Max. glass size : 2500*3500

washing brushes : 6 pieces

Flat glass thickness : 3-15mm

Automatic Jumbo Size Insulated Glass Production Line With Argon Gas Filling

Automatic Jumbo Size Insulated Glass Production Line with Gas Filling

Main feature of Jumbo Size Insulating glass Productione Line

● Applicable to produce triple IG and shaped IG

● Online display of washing speed

● Intelligent intermittent work, saving energy

● Germany Siemens PLC control system,touch screen interface

● 3pair soft brushes can wash online and offline Low-E glass

● Automatic identification of coated and Low-E glass

● Water tank with automatic temperature control and water washing system

● Air heating system

● Air Fan automatic start and stop setting

● Noise reduction system

● The washing machine adopts SS material and waterproof device

● Adjustable pressing board to keep the plate pressing surface straight

● Connection mode of aviation plug

Details of Jumbo Size Automatic Insulating glass production line :

• Jumbo size Automatic Insulating glass production line has 7 sections:

01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.

• 01 transfer section

Coating detection mechanism, automatic detection of offline Low-e film

• 02 washing machine

Main feature:

• Using 6 pieces of soft brushes with 0.1mm soft hair, can wash low-e glass

• European silencer system

• Stainless steel material

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• Water tank automatic temperature control, water replenishing system

• 03 discharge section

• Storage glass

• 04 inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass.

• 05 transfer section

• Automatic measurement of glass thickness. It can be used according to actual needs when working.

• 06 pressing and filling section

Main feature:

• Ultra-long glass can be compressed by twice

• Adopts conveyor belt to transfer glass, use servo motor to press glass

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• 07 discharge section

• Storage glass

• Can be connected to sealing machine

Options of Jumbo size Automatic double Glazing glass line with gas filling

1. Pre-washing

2. Automatically accurate positioning for 3 or 4 side step IG

3. Automatic gas filling can set gas value and display the processing of filling online with high gas concentration

Parameter of Jumbo Size Automatic Insulated Glass Production Line

| Unit | LJBZ3370 | |

| Voltage | 380V50Hz3P | |

| Total power | KW | 54.5 |

| Washing speed | m/min | 2-10 |

| Maximum working speed | m/min | 45 |

| Minimum glass size | mm | 450*280 |

| Maxmum glass size | mm | 3300*7000 3000*3000 (Double press) |

| Flat glass thickness | mm | 3-30 |

| Washing brushes | Pieces | 6 |

| Maximum thickness of insulating glass | mm | 80 |

| Total gas consumption | L/min | 1500 |

| Conveyer roll height | mm | 520 |

| Dimension (L*W*H) | mm | 47200*3500*4500 |

1. What does our company do ?

LIJIANG GLASS is the manufacturer in Jinan city, China since 2012 year. We make the IG line, Insulating glass sealing robot, spacer bending machine, butyl extruder machine desiccant filling machine and so on, porviding machines for all over the world with after sale service.

2. How to provide after-sales service ?

For India and the market aroud India, we have two Indian loal engineers, they can provide service in time.

For South America market, we have one engineer there to provide service.

For other market, we have the engineer team with 10 - 20 years experience, they will go to foreign customers' factory to install machine, train workers and provide after sale service in time.

Since the virus of the whole world, Our engineers are restricted to many countries in the world. So we provice installation service and trainning work online by Wechat, Whatsapp and so on. Once the world has a better suitation, our engineer will go to check our machines again.

3. What is the IG line ?

The types of the IG line are without filling argon and with filling argon gas. There are also two special IG lines, air floating IG line and super fast IG line (washing and pressing two IG units together).

The IG line is calles insulating glass processing line, it includes glass washing machine, spacer frame installation and glass pressing machine. We normally have 2000*2500, 2500*3500, 2500*4000 ,2500*4500 and 3300*7000 IG line.

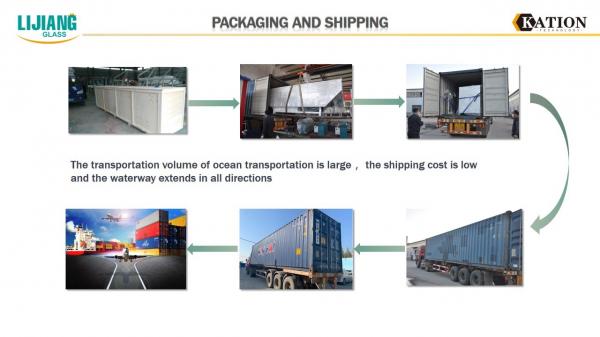

4. How to package production line ?

One set of IG line normally needs two containers when shipping to foreign country, 2 pieces of 40HQ containers.

Electrical parameters

| NAME | ORIGIN | BRAND |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Servo motor for step glass | Japan | FUJI |

| Photoelectric switch | Germany | SICK |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| Touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Brush motor | China | QINGHUA |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

Pictures of Jumbo size automatic insulating glass production line

Related Products of LIJIANG GLASS

Vertical Automatic Glass Washing and Drying Machine

Feature of Vertical Insulating Glass Production Line

1. Adopt unique inflatable structure to ensure fast inflation speed, high inflation content and save air source

2. It can be connected with factory ERP and MES, from equipment with separate functions to automation, and then to intelligence.

3. There are two plate presses, which can be used individually or at the same time. Making small glass is to process two pieces of glass at the same time to improve the efficiency of the whole line.

Product Details of IGU Line

Cleaning section

The washing machine body is made of high-thickness 304 stainless steel plate, which is sturdy and durable.

With automatic glass thickness measuring device, no need to set glass thickness separately, automatic cleaning, scientifically avoid tedious manual adjustment of more than 8mm, and the maximum thickness can be cleaned to 30mm.

The brush bearing and bearing seat are important parts of the sweeper, which are easy to be damaged due to high rotational speed. Our company adopts thrust self-aligning ball bearings, which are more durable and stable than other rubber and plastic materials.

Air drying room

The air knife can automatically adjust the opening and distance according to different glass thicknesses.

The adjustment structure adopts mechanical structure with high stability.

Glass of different thicknesses can be cleaned continuously without manual adjustment of the air knife. The effect of making laminated insulating glass is better

Frame section

The advanced screw adjustment structure design is adopted, and the positioning accuracy of the aluminum frame is high.

The aluminum alloy guide is light and smooth, and can be automatically adjusted according to the height of the glass.

The overall design is hollow, and a maintenance rear door is installed to facilitate cleaning of the stains on the back of the glass.

Pressing method: servo motor timing belt

The servo motor timing belt method is adopted to ensure the ultra-high precision pressing of glass and the pressing speed. Can make extra-large, extra-thick glass.

Tech Parameters of Vertical Glass cleaning and Drying Machine

| Power supply | Voltage(V) | 380 |

| Frequency (Hz) | 50 | |

| Main power | kW | ≈35 |

| Washing speed | m/min | 1~7 |

| Max high speed | m/min | 10 |

| Min glass size | mm | 450×280 |

| Max glass size | mm | 2500×4000 |

| Glass thickness | mm | 3~15 |

| Roller height | mm | 500±20 |

| Total weight | kg | ≈3500 |

Advantage of glass washiing machine

•Using 3Pair of soft brushes with 0.1mm soft hair, can wash low-e glass

•Pre-washing (Optional)

•The air knife can automatically adjust the width of the air knife according to the thickness

•New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

•European silencer system

•The operation box with washing speed display, can accurately display washing speed (8-10m) •Water tank automatic temperature control, water replenishing system

•Stainless steel material

Detail of AutomaticGlass Washing Machine

Introduction of LIJIANG GLASS

|

|

Automatic Jumbo Size Insulated Glass Production Line With Argon Gas Filling Images |